Commercial, Industrial & Extreme Duty Vacuum Cleaners

Hydro Master Vacuum Tanks

Hydro Master Tank Vacuum System

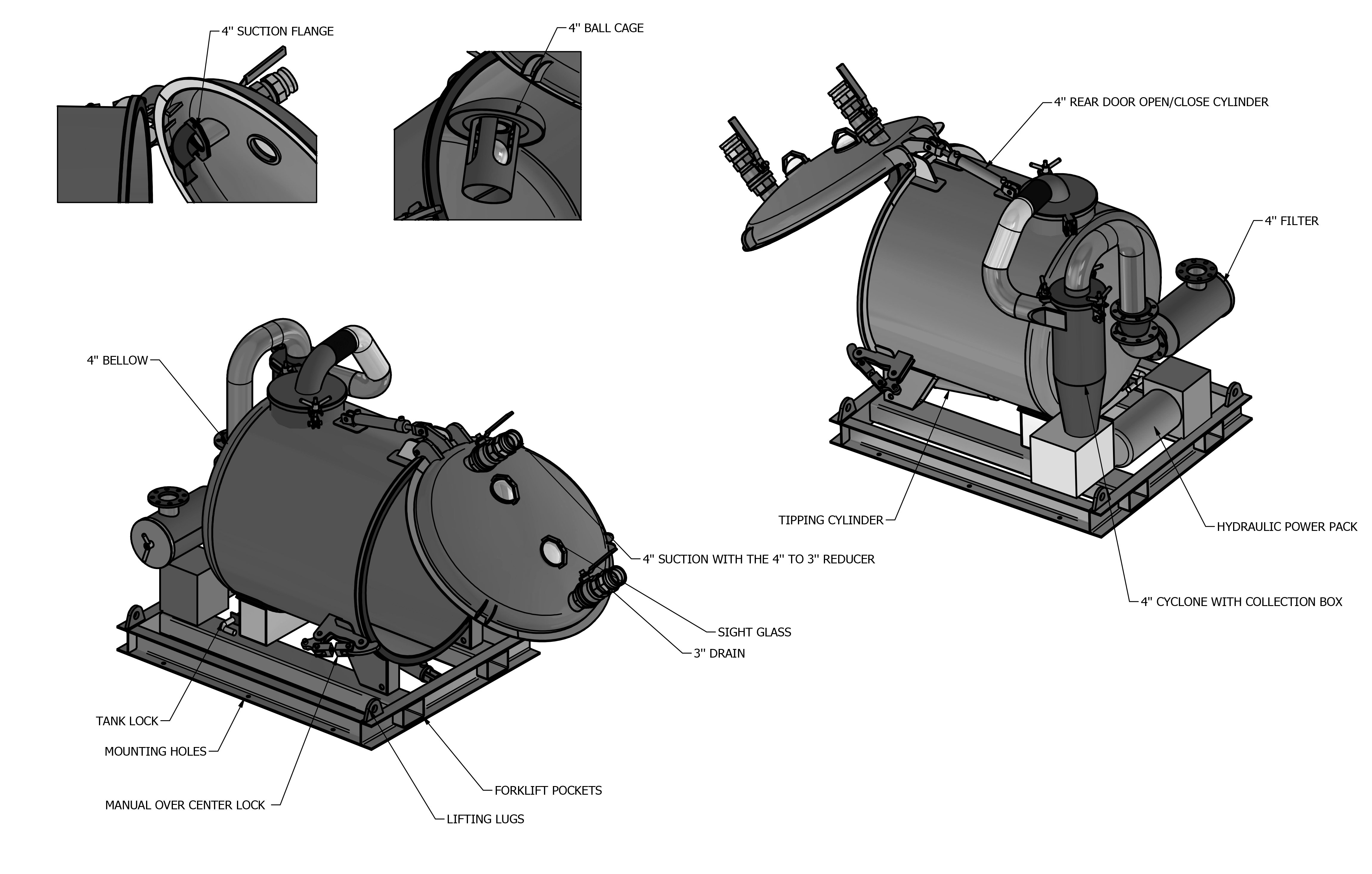

Hydro Master is an innovative tipping tank system designed for a wide variety of waste, including liquids, roof gutter debris, and much more. It includes an integrated hydraulic tipping system, triple filtration for debris protection, a liquid waste valve for handling fluids, and convenient forklift pockets for easy mounting and installation of the system. This advanced system offers unparalleled efficiency and convenience for cleaning contractor.

Main Features

-

Hydraulic tipping with remote

-

Hydraulic opening door

- Triple filtration

- Waste discharge chute

- Forklift pockets

- High liquid shut off valve

- Safety lock for transport

- Stainless steel piping, cyclone

- Stainless steel filter housing

- 6mm hi carbon steel vessel

- Rated lifting lug points x 4

- Australian designed and manufactured

- 2 site glasses on opening door

- 24 volt compact deep cycle batteries

- Proprietary door locking clamps

- Replaceable stainless steel inlet waste deflector

Cyclonic Triple Filtration

This advanced filtration system serves as a formidable defense against fine dust and debris, ensuring that only clean air reaches the vacuum filter. This ingenious design not only enhances the longevity and performance of the vacuum filter but also guarantees a much longer work time before cleaning the filters. Made entirely from stainless steel, it ensures longevity with no rust forming.

Hydraulic Tipping with Remote

The hydraulic tipping mechanism provides users with effortless control through a user-friendly remote pendant. The hydraulic tipping system allows for swift and precise tilting of the tank, facilitating quick disposal of collected debris. With its seamless integration and intuitive operation, the hydraulic tipping feature redefines convenience and productivity. The 24-volt system also has an isolator switch to prevent activation.

Waste Discharge Chute

To handle liquid waste quickly and efficiently, a large stainless-steel valve is fitted. The waste discharge chute is strategically integrated into the tank frame, offering a seamless outlet for the disposal of waste without the mess. Whether it's rainwater, sludge, or other liquid substances, the chute efficiently directs them away from the tank. The inclusion of this intelligent feature ensures not only a thorough and effective cleaning process but also minimizes the need for manual handling and additional equipment. Users can now tackle a wider range of cleaning tasks, streamlining the entire process and optimizing productivity without making a mess on the trailer or vehicle.

Forklift Pockets

Built-in forklift pockets enhance the lifting and moving of the complete unit. These forklift pockets are strategically integrated into the tank's design, providing secure and convenient lifting points for a forklift. Additional rated lifting lugs are also included.

High Liquid Shut Off Valve

This mechanism detects liquid levels. When the liquid nears full capacity, the High Liquid Shut Off Valve springs into action, automatically halting the vacuum flow to prevent any water from going to the vacuum producer.

Safety Lock for Transport

Equipped with vessel supports to hold the structure in the working and transport positions, ensuring the vessel does not move. A tipping mechanism safety lock ensures the vessel does not lift during transport.

Stainless Steel Piping, Cyclone

Most items are constructed from stainless steel, including piping, cyclone, filter housing, brackets, and fittings. This guarantees exceptional durability, maximizing equipment longevity. The cyclone separator optimizes performance by efficiently separating fine dust from the airflow and maintaining peak suction power. With the easy-to-clean stainless steel filter housing, maintenance becomes hassle-free.

Rated Lifting Lug Points

The unit is equipped with rated lifting lug points, ensuring safe and effortless handling. These specially designed lug points are rated to specific weight capacities, providing clear guidelines for secure lifting operations. With their strategic placement and robust construction, the rated lifting lugs promote efficiency and safety during the tank's mounting and fitting.

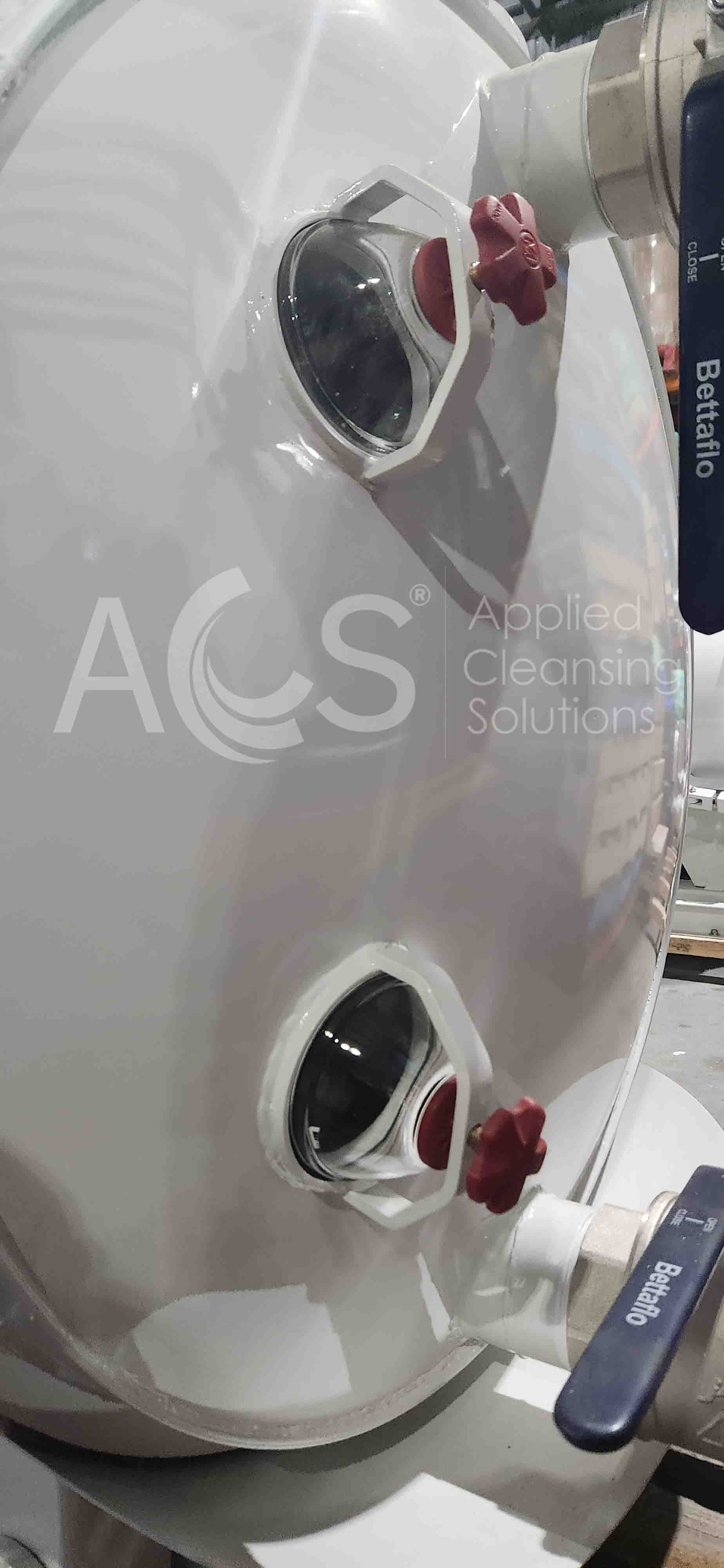

Site Glasses on Door

Two site glasses on the door, one at the bottom and another at the top, provide valuable visual indicators of the liquid levels inside the tank. The bottom site glass allows for easy monitoring of the liquid accumulation during operation, ensuring you can promptly detect when the tank reaches its capacity. The top site glass complements this functionality, enabling a quick visual check of the liquid levels without the need to open the door, streamlining your cleaning process and enhancing overall efficiency. With these dual site glasses, you can maintain precise control over the tank's liquid content.

Stainless steel Ball Valves

2 x 4-inch stainless steel ball valves are fitted with camlock fittings. This feature allows for the quick drainage of liquids prior to opening the vessel; the top valve ensures no material exits the tank when tipping.

Inlet Deflector

The opening door is fitted with a replaceable inlet deflector, ensuring that the material is directed to the rear and bottom of the vessel and allows for the efficient filling of the whole vessel. The deflector is made from stainless steel.

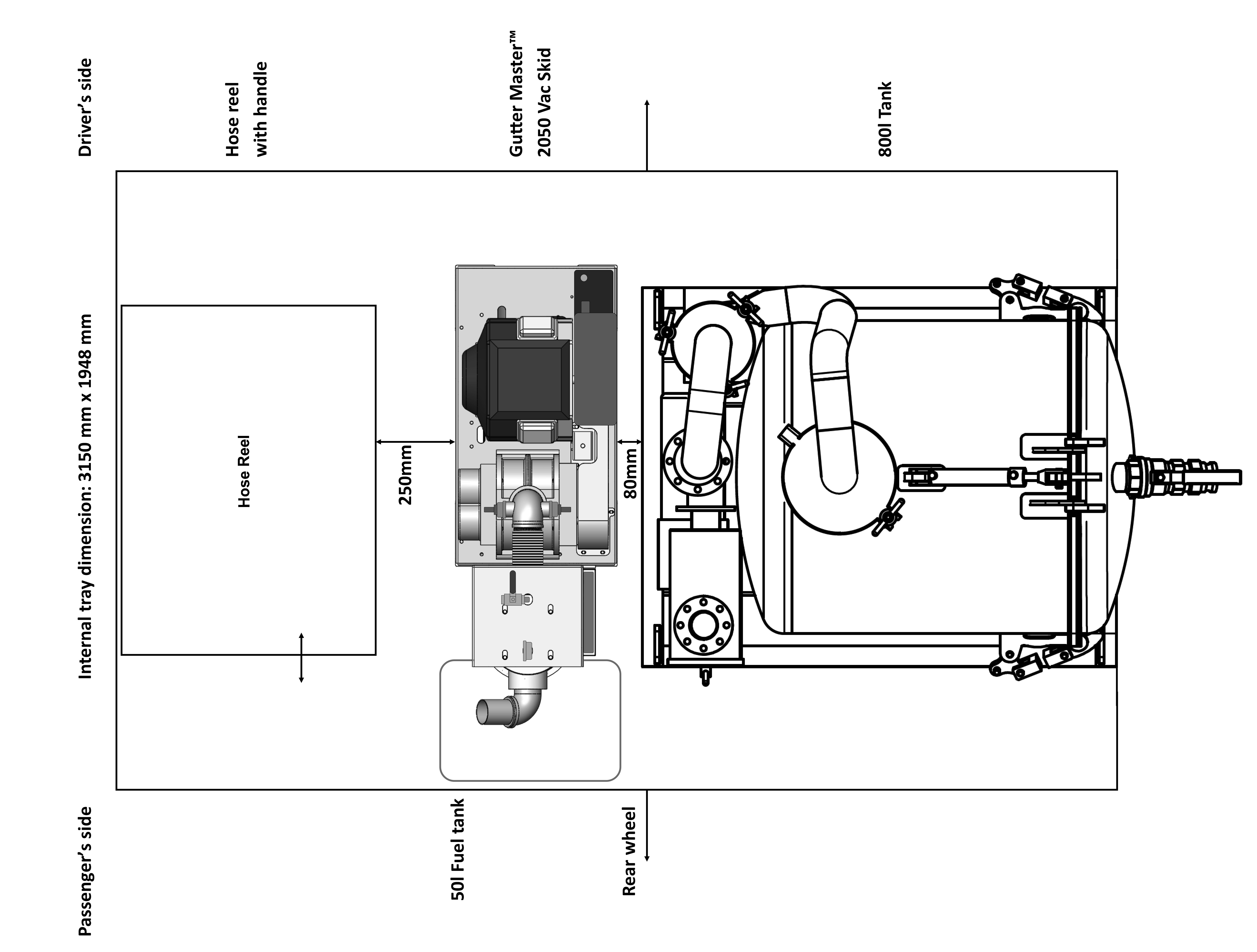

Short Wheel Base 3 Ton Tray Truck