Gutter Master® 2050 Machines

Manufactured & designed by ACS® for 7 years, Generation IV, Often Emulated Never Equalled

Engine Options

Now you can option a Vangaurd 23hp, iGX700, iGX800 Honda engine with our Gutter Master™ 2050 vacuum systems

-

Key start Honda GX690 standard issue

-

60mts x lightweight industrial grade 63mm smooth bore vacuum hose

-

Various gutter vacuum tools

-

High liquid shut off valve

-

Drum handling waste tipper

-

Australian made system

-

Industrial vacuum relief valve

-

Poly marine fuel tank with gauge

-

205 litre waste drum and stainless steel cyclonic interceptor drum top head

-

Laser cut steel vacuum hose reel

-

Belt drive system with service access

-

Australia's most powerful modular gutter vacuum system

-

Easily handles medium to heavy excavation jobs

7 Years of Manufacturing, Generation IV

Gutter Master® 2050

Industrial Gutter Vacuum System

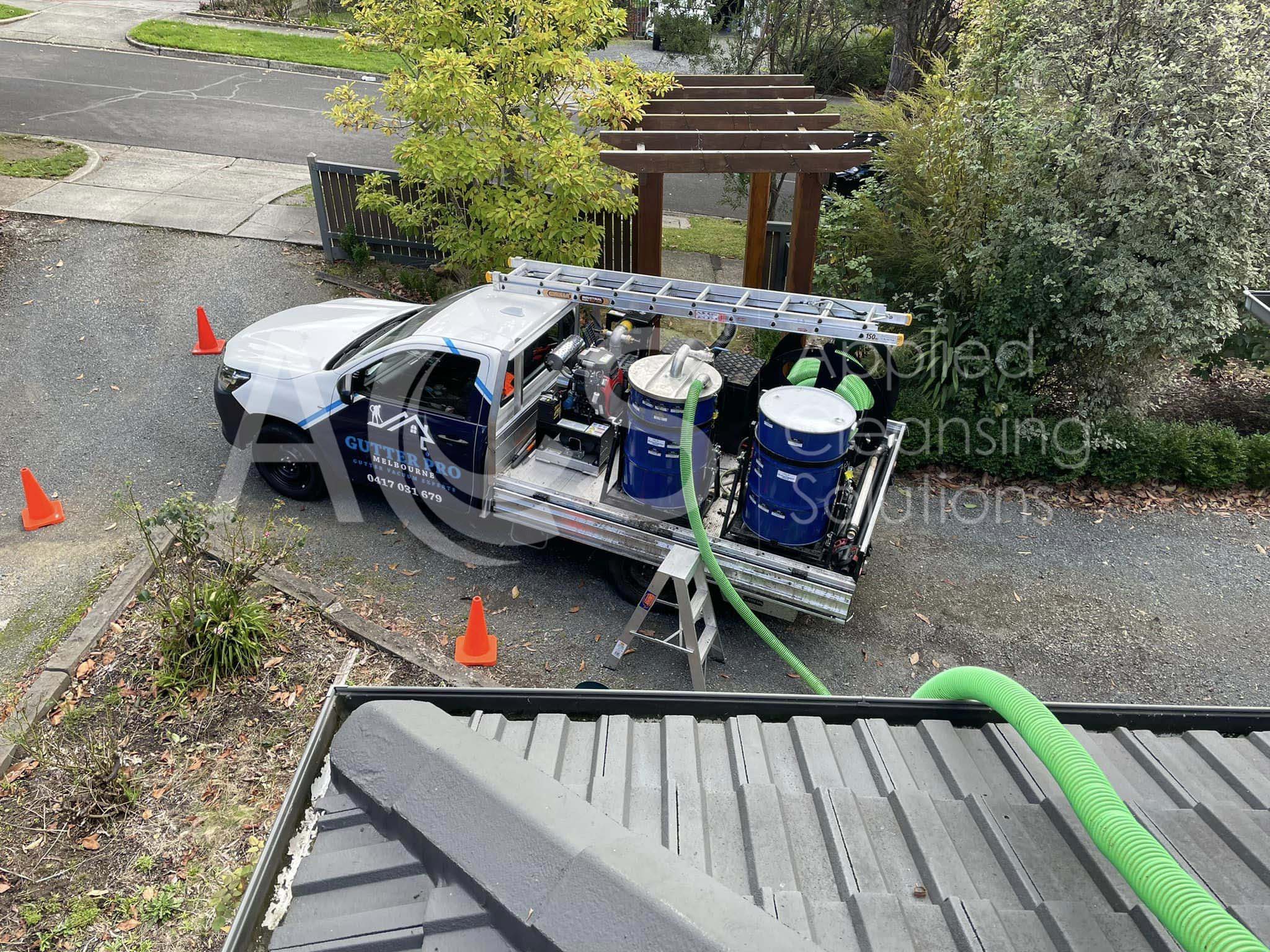

The Gutter Master® 2050 systems weighs just over 420 kg complete with a 205 Litre drum/tipper and hose reel configuration and is only 1000 mm high, making it utility tray and single axle trailer safe and friendly.

Check out the weights and dimension of competitors machines nothing comes close!, we've even had clients that have fitted a Gutter Master® 2050 into their commercial vans.

Most of the important components of the Gutter Master® 2050 are manufactured from stainless steel and will never rust, however typical competitor machines are manufactured from mild steel.

The Gutter Master® filtration system is proven with over 400 units in operation since 2007. The Gutter Master® 2050 industrial gutter vacuum system will provide you with all the grunt you will ever need. Built on a specially designed wrinkle finish power coated skid/platform to be the most compact system of its kind.

Gutter Master® 2050

No Compromise Top of the line Components Provides Confidence

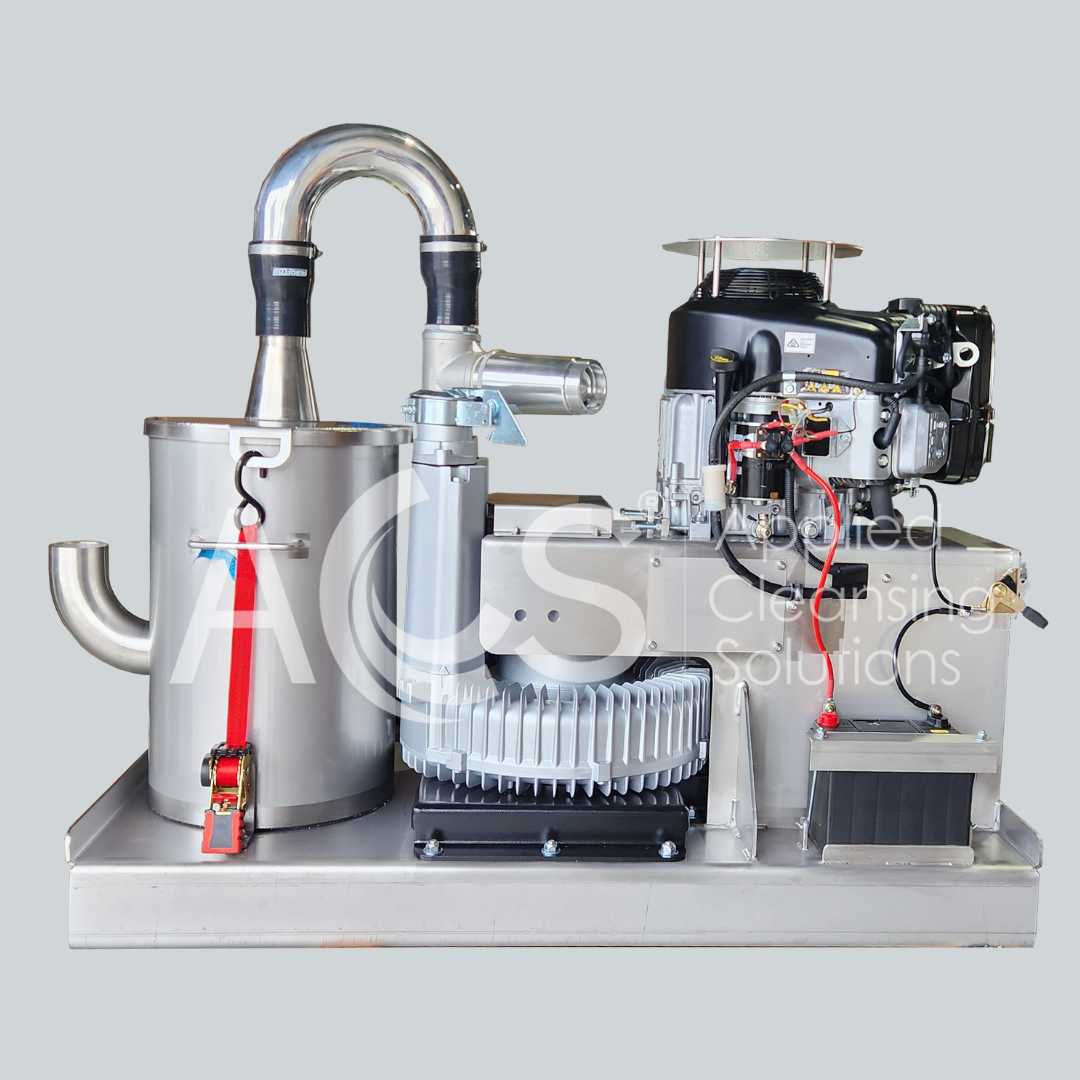

A Vanguard 23 hp 4 stroke engine is used to drive the Tuthill blower via a twin belt industrial drive system, a service portal is easily accessible to enable simple belt tensioning requirements. The engine is supplied with a worldwide 3 year warranty backed by Briggs & Stratton™. Of course all this power needs protection to ensure the system continues to operate trouble free, an over pressure relief valve is fitted to protect the Tuthill blower from overheating. The clear polycarbonate filter housing is fitted with a wet and dry cartridge filter and pre filter to prevent dust contamination into the Tuthill blower. All other components are either manufactured from stainless steel or have received an industrial powder coated finish to protect them from the day to day elements.

We have tested the Gutter Master® 2050 to hose lengths of 80 metres, did it lose power no way, did it slow down, yes a little, but this system just kept pulling out gutter channel waste.

The clear polycarbonate filter housing includes a large capacity wet and dry filter and can be easily removed for cleaning. A stainless steel fuel tank holder has been integrated into the skid to support a marine style poly fuel tank with a gauge makes refuelling simple and safe.

Gutter Master® 2050

Permanent high efficiency dust filter protects your investment

Gutter Master® 2050 features a long life high efficiency dust filter system. The dusty air is filtered by a large primary air filter that is suspended in a clear polyester this material can be washed clean 100’s of times and re used. It is one of the world's highest quality air filtration media available. This superb filter textile has an extremely high dust rejecting surface and dust will not easily clog . With Gutter Master® 2050 filter system you will not need to spend any further monies on continually purchasing new filters.

Another first from ACS® is our stainless steel 210 litre Gutter Master® conical waste hopper with bottom discharge opening gate, this allows you to empty waste after every job into a typical plastic basket (supplied) lined with heavy duty plastic bags. Now you can empty into bags, tie them off and deal with them at the end of the day if you are not able to dispose of the collected waste at your clients premises. This collection receptical is optional. Standard is the 205 Litre collection drum.

Components, like the drum top cyclonic interceptor (stainless steel), hose reel (industrial powder coated), alloy light weight vacuum tools and even our ACS™ specification clear and light weight vacuum hose are designed to be a complete engineered system.

This machine will easily handle all types of material found in roof gutter channels and also provide you with the ability to deliver vacuum

- Flooded basements

- Bird droppings

- Cavity

- Sludge

- Pressure washer water recovery

- Pit cleaning

- Vacuum excavation services

We first offered mechanised locally designed and manufactured gutter vacuum systems back in 2006 and today we still offer our clients the best systems, best warranties and the best after sales support.

Designed and manufactured in Australia and exported to international markets, the Gutter Master® brand continues to innovate and is the only modular complete engineered gutter vacuum system available.

Thinking of getting involved in the lucrative Gutter vacuum cleaning market, call us and discuss your needs and requirements, we can arrange easy finance options , teach you how to use the equipment and deliver safe efficient services that will allow you to make money from day 1 of purchase.

Not sure how to set up the system on your vehicle or trailer just ask, we have installed over 200 systems onto clients vehicles/trailers we will have a design layout to fit.Do you want a custom set up with large waste tanks, twin operator systems and or fitted onto a specific set up, contact us to discuss your specific requirements. As all fabrication and design is done in house and right hear in Australia you can be assured that the finished system will be correct the first time.