Vac Loader 3550 Electric

- 30kw/50AMP/ 4 pin/three phase

- Variable speed or Inverter drive

- Soft starts/shut downs

- 35 M2 per minute airflow. (1200CFM)

- Precision engineered blower

- Three lobe positive displacement

- Negative pressure to -60kPA. (17 Hg)

- Suits in house plant Vac/loading

- Forklift around plant

- Up to 100 meters 4 inch hose

- Anti-static rubber heavy duty type

- Skid or trailer mounting options

- Optional , removable swivel castors

- Australian designed & manufactured

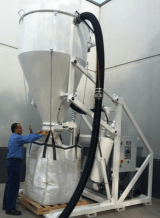

High Performance Vacuum Loaders in 3 Phase Electric or Diesel Engine options

VacLoaders were developed specifically to provide a viable alternative to the high cost of conventional vacuum trucks. They have the superior ability to recover and bulk bag load all transferred product.

VacLoader's are Powerful and Versatile

As either a stand-alone unit, or part of a ring main ducted system, VacLoaders provide high performance recovery of almost any dry material from fine powders to crushed rock. The 1.2m³ hopper, allows material to be gravity discharged into a bulk bag, skip bin, truck or any other container.

The hopper hydraulically elevates, providing just under a two metre ground clearance. Discharge of material is through a proven, simple, yet robust, 400mm diameter valve, pneumatically opened and closed. Continuous reverse air pulse cleaning of the baghouse filter system ensures maximum performance without loss of suction. An integrated vane type air compressor provides independence from plant or external compressed air supplies. Wireless radio remote control of vacuum power settings as well discharge gate opening and closing operation is included.

VacLoaders uniquley feature automatic weight control for accurate bag loading

Available powered by either a Three Phase Electric or Turbo Diesel Drive.

The compact design of the VacLoader range complements our trailer or truck mounted series of Vacuum Loaders with even lower noise levels, greater portability and at a much lower purchase cost. Minimal maintenance requirements and ease of servicing for industry were vital factors in the VacLoaders' development.

VacLoaders represent an excellent investment in a high performance industrial vacuum system. They will be of immediate benefit as a time and money saving business tools that would quickly pay for themselves in the increased safety and/or productivity of your operation.

Technical Specifications

- 30kW / 50 Amp / 4 Pin / Three Phase electric motor drive.

- Variable Speed or Inverter Drive for soft starts / shut downs

- 35 M2 per minute airflow. (1200 CFM)

- German or Italian precision engineered three lobe positive displacement blower.

- Negative pressure to -60 kPA. (17Hg)

- Suited to in-house plant vacuum loading operations.

- Easily forklift movable around plant.

- Optional, removable, braked swivel castors for relocation into tight access areas.

- Up to 100 metres of 4 inch heavy duty anti-static rubber vacuum hose.

- Skid or Trailer mounting options.

Materials Handled

Bulk vacuum a wide variety of dry, dusty, powdered or granular materials such as:

| Abrasives (Shot) | Alumina | Aluminium Chips |

| Asbestos | Ash | Bark Chips |

| Brick Chips | Carbon Black | Catalysts |

| Cement | Ceramic Particles | Cereals |

| Chemicals (Non Corrosive) | Clay (dry particles) | Clinker |

| Coal Chips | Cullet | Dust / Dirt |

| Fertiliser | Flour | Grains |

| Lead Oxide | Limestone | Metal Chips |

| Mill Scale | Mineral Wool | Ore Pellets |

| Oxides | Perlite | Refractory Grit |

| Shredded Paper Dust | Sand | Sawdust |

| Slag Particles | Slurries (Dry) | Stones (up to ±75mm) |

| Vermiculite | Wood Chips | Zeolite |

Automatic Filter Cleaning System

The VacLoader onboard compressor supplies the continuous reverse pulse filter cleaning. HEPA filtration is also available.

Automatic Product Weighing

All VacLoaders will assess the weight of materials being vacuumed. At the selected weight level the loader automatically returns to standby mode. This unique feature enables the capture and discharge of an exact amount of material each and every time.

Readily connects to new or existing ducted ring mains systems

VacLoaders will easily interface with any existing steel pipe ring main system. We can advise on supply and installation of a new system.

Vacuum loads into bulk bags

VacLoaders readily discharge materials directly into spout top Bulka Bags or other vessel. Spilled materials can be returned onto a conveyor line. This is an efficient method to recover valuable bulk product for reuse or storage.

Continuous Duty Cycle

VacLoader's are designed for continuous 24 hours per day, 7 days per week duty cycle.

Vacuum Loader Customers

| Alcoa Aluminium | Austral Bricks | BHP Billiton Port Hedland |

| Blue Circle Southern Cement | Bluescope Steel | Bluescope Steel |

| Boral Plaster | Boral Plasterboard | Caltex Refinery |

| Hydro Aluminium | James Hardie Industries | Kellogs |

| McElligotts Industrial Painting | Multiserv Port Kembla | One Steel Rooty Hill Mini Mill |

| Orica Chemicals (Perlite) | PGH Bricks & Tiles | Readymix Quarries |

| Transpacific Services | Tomago Aluminium | Veolia Enviro Services |

For an obligation free discussion to find out how the versatile VacLoader can save you time or make you money, simply pick up the phone and call us on 03 9769 1211