- 3 phase 20 amp requirement

- Powerful 580 cfm

- Huge pulling power of -35 kpa

- Seperate bulk capacity 205 Drum and Interceptor head

- Up to 60 metre working capability

- Available in 51mm or 63mm vacuum hose

- Wet and dry capabilities

- Continuous duty performance

- Armortex Teflon filter

- Optional castor wheels for skid

Gutter Master™ 1530 DISCONTINUED

We have discontinued manufacturing the 1530 due to certain electronic components are no longer in manufacture.

1150mm x 750mm stainless steel skid chassis with dual forklift pockets

Triple high performance bypass vacuum producers

560cfm per min volumetric airflow

Liquid level shut off float

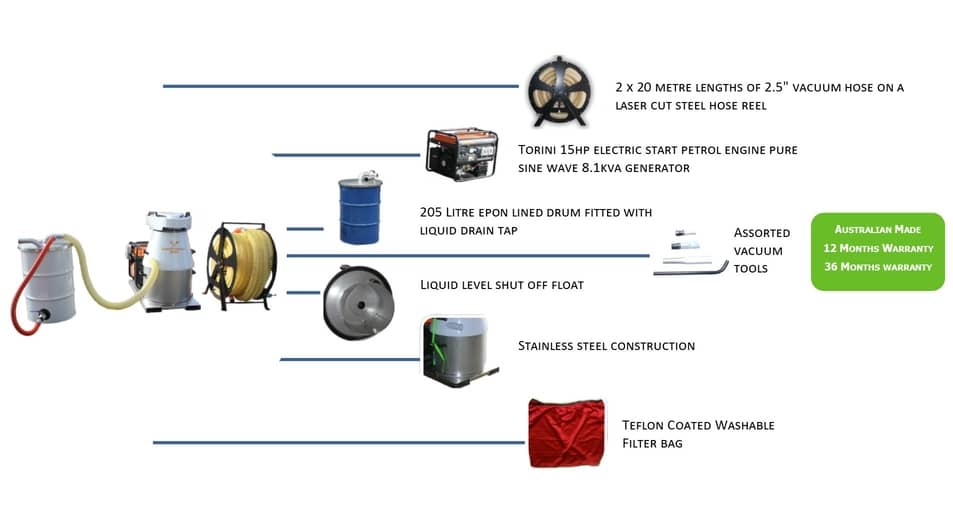

2 x 20 metres of 2.5 inch smooth bore vacuum suction hose

Assorted gutter cleaning tools

Laser cut large capacity hose reel

205 Litre waste collection drum with liquid drain tap

Torini electric start engine

Worksafe approved RCS's

Drum tipper (optional supply)

Plastic bag collection of dry waste (optional supply)

Australian designed & manufactrured

Gutter Master™ 1530

Industrial Gutter Vacuum Syste

Our Gutter Master™ systems weigh just over 200kg complete with a 205 Litre drum and hose reel. Most of the components of the Gutter Master™ 1530 are manufactrued from stainless steel and will never rust, however typical competitor machines are manufactured from mild steel.

The Gutter Master™ system and our filtration system is proven with over 300 units in operation. Your purpose engineered, complete gutter leaf, twigs and silt cleaning system. As the professionals choice it was specifically developed for fast and profitable gutter cleaning. Over the past 10 years Gutter Master™'s 1530 design specifications have been continuously improved and refined based upon constant feedback obtained directly from operators already working in the industry. A proven performer working across Australia.

Gutter Master™ 1530

Clean Roofs And Gutters The Professional Way

Hand scoop cleaning gutter channels and roof valleys can be a tiring and time consuming process. Hanging onto a ladder or crouching down at a roof line edge can become hard on your knees, ankles and feet. Wet, messy, gutter slop often has to be hand scraped into buckets that get heavier as you move along. By flicking the muck down to the ground and using regular blower vacs, you just end up having to double handle the silt you threw or leaves you blew off the roof.

Gutter Master™ 1530 is powered by three large, maintenance free, electrically driven vacuum suction motors. Technical specifications are an impressive 15 cubic metres per minute (560 CFM) of free airflow . Your Gutter Master™ generates around 3 times the airflow and higher vacuum pressures when compared against regular drum type industrial vacuum cleaners.

Gutter Master™ 1530

No Compromise Top Of The Line Vacuum Suction Motors

The vacuum producers used to drive your Gutter Master™ are the latest technology. They are the most powerful in their class available anywhere in the world. These new high quality, United States made vacuum producers spin up at an amazing 34,000 RPM.Thermal and electrical overload protection is already built in so that they will not affect power circuits. Featuring a new high efficiency cooling system with tangential exhaust air ports. They have a patented liquid proof air sealed bearing system. This means that accidental water ingestion directly through the unique impeller housing will not ruin them like regular vacuum motors.

Gutter Master™'s special vacuum motors are made for us by a specialist manufacturer who are now in their 103rd year in business. They have acquired an enormous amount of engineering experience. Over a century they have solved a huge number of technical challenges to make these ultra-powerful devices. These state of the art vacuum producers will outperform all competitors in their class.

Gutter Master™ 1530

Permanent High Efficiency Dust Filter

Gutter Master™ 1530 features a long life high efficiency dust filter system. The dusty air is filtered by a large primary air filter that is suspended above the main capture drum. Featuring a proven textile filter technology known in the filter industry as Armour-Tex. It is one of the world's highest quality air filtration media available. This superb filter textile has an extremely high dust rejecting Teflon coated surface. Dust will not easily clog the filter. A simple manual shake to clean the filter is a completely dustless process. Your filter remains in place during the very easy 10 second cleaning process. With Gutter Master™ 1530 you will not need to spend any further monies on continually purchasing new filters.

If desired the Gutter Master™ 1530 can uniquely vacuum recover the collected leaf litter and silt directly into heavy duty, 205 litre steel drum liner plastic bags. Nearly all competitor vacuum equipment can only dump the messy collected waste directly onto the ground. A typical 4 bedroom house with heavy tree leaf litter and silt filled gutters might generate around a quarter of a drum of of waste. A quarter drum bag of leaves, twigs and silt will weigh a Health & Safety friendly ±15 kilograms. Of course, if you choose to empty the bag more frequently then the total bag weight is not an issue.

In some cases, by consent, this collected material can be discarded into the householder's green waste bin (if supplied by their local council). Alternatively, the collected material can be used to make an excellent, nutrient rich, saleable, garden compost. As your Gutter Master™ vacuums directly into heavy duty plastic bags there is no need to double handle the collected organic material. Your machine's primary collection drum is removable for cleaning if required but does not need to be tipped out.

Gutter Master™ 1530 DISCONTINUED

We have discontinued manufacturing the 1530 due to certain electronic components are no longer in manufacture.

- 1150mm x 750mm stainless steel skid chassis with dual forklift pockets

- Triple high performance bypass vacuum producers

- 560cfm per min volumetric airflow

- Liquid level shut off float

- 2 x 20 metres of 2.5 inch smooth bore vacuum suction hose

- Assorted gutter cleaning tools

- Laser cut large capacity hose reel

- 205 Litre waste collection drum with liquid drain tap

- Torini electric start engine

- Worksafe approved RCS's

- Drum tipper (optional supply)

- Plastic bag collection of dry waste (optional supply)

- Australian designed & manufactrured

Key Start 23 HP Vanguard VTwin engine driving a regenerative vacuum producer

40mts x lightweight industrial grade 63mm smooth bore vacuum hose

Various gutter vacuum tools

High liquid shut off valve

Drum handling waste tipper

Easily handles light excavation jobs

Industrial vacuum relief valve

205 Litre waste collection drum with cyclonic interceptor

Laser cut steel vacuum hose reel

Belt drive system with service access

Australian made system

Stainless steel vacuum/ engine platform

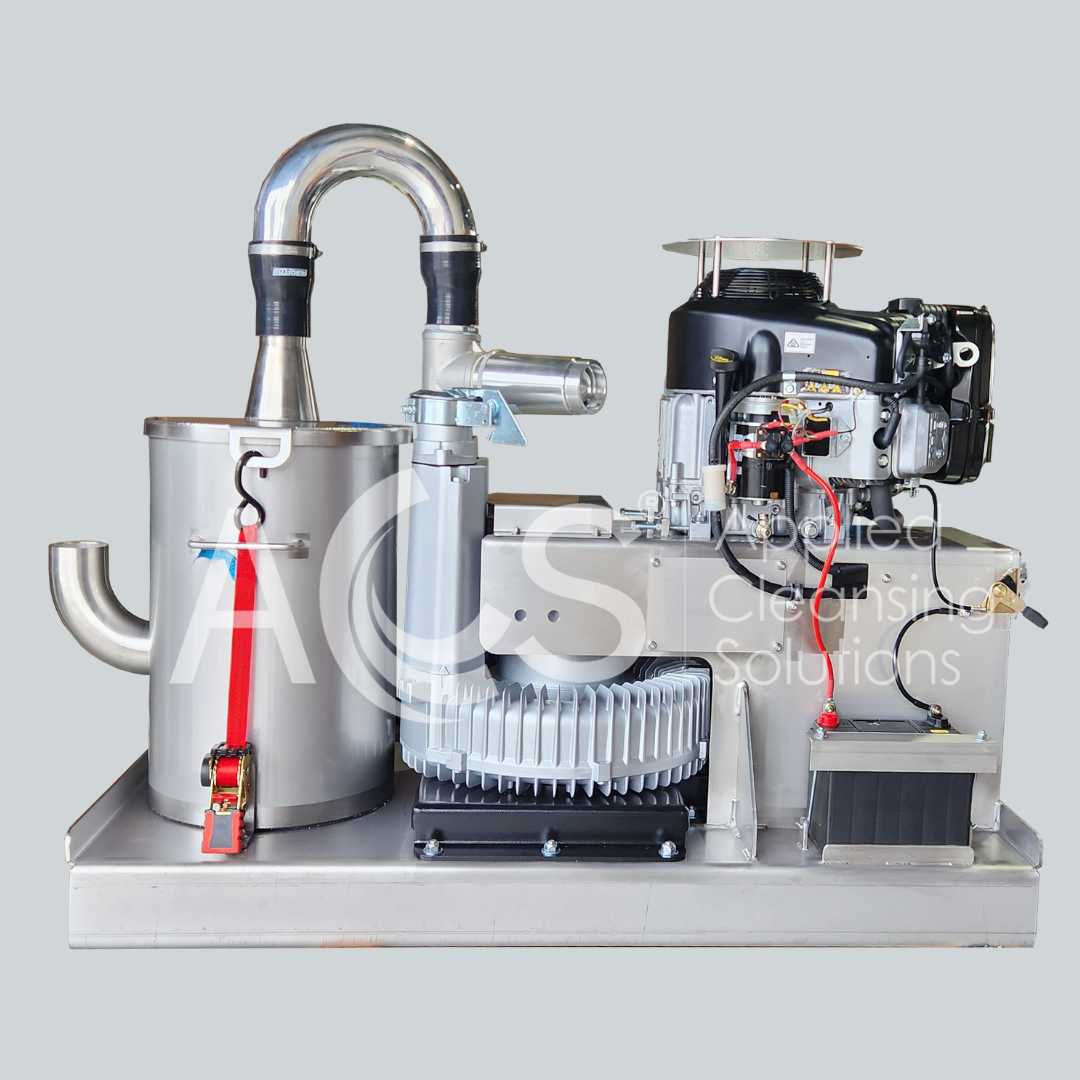

Gutter Master® 2040

Industrial Gutter Vacuum System

Our new generation Gutter Master® 2040 gutter vacuum system built for external vehicle mount applications, is now one of our most popular models. The engine, vacuum blower and filter housing is housed on a 5mm thick stainless steel skid /platform with integrated securing points and forklift pockets. Even the entire filter housing, vacuum inlets and outlets are made from stainless steel.

Check out the weights and dimension of competitors machines nothing comes close!, we've even had clients that have fitted a Gutter Master® into their commercial vans.

The integrated marine style poly fuel tank with gauge makes refueling simple and safe. This machine has not been designed and built to a price, it has been built to last. The engine comes with a 3 year warranty from Briggs & Stratton™ who is based right here in Australia, the blower comes with an ACS® backed 2 year warranty.

The engine on the Gutter Master® 2040 is a 23hp Vanguard key start engine, drive is via a twin belt system to an industrial regenerative vacuum producer that is basically maintenance free.

- Bird droppings

- Ceiling cavities dust

- Rainwater tanks sluge

- Pressure washer water recovery

- Small pit cleaning

Gutter Master® 2040

Used by professional service and facility management companies Australian wide

A Vanguard 23 hp 4 stroke engine is used to drive the industrial vacuum blower via a twin belt industrial drive system, a service portal is easily accessible to enable simple belt tensioning requirements. The engine is supplied with a worldwide 3 year warranty backed by Briggs & Stratton™. Of course all this power needs protection to ensure the system continues to operate trouble free, an over pressure relief valve is fitted.

We have tested the Gutter Master® 2040 to hose lengths of 40 metres, did it loose power no way, did it slow down, yes a little, but this system just kept pulling out gutter channel waste. The extremely lightweight design of the Gutter Master® 2040 make this system popular with facility management companies who require an industrial gutter vacuum system that can be fitted onto a single cab ute that can gain access to multi housed establishments like aged care facilities and housing comunities.

At under 1100mm high and weighing in at under 340 kg the Gutter Master® 2040 has proved to be a cost effective gutter vacuum solution with many large companies Australia wide.

This machine will easily handle all types of material found in roof gutter channels and also provide you with the ability to deliver vacuum cleaning services to

Gutter Master® 2040

Fully stainless steel construction will provide lifetime chassis integrity

Gutter Master® 2040 is the only modular vacuum system that is manufactured entirely from stainless steel and will still look like a new engine/vacuum platform after many years of use.The Gutter Master® 2040 aslo features a long life high efficiency dust filter system. The dusty air is filtered by a large primary air filter that is enclosed in a removable stainless steel filter housing. Featuring a proven textile filter spun bonded polyester this material can be washed clean 100’s of times and re used. It is one of the world's highest quality air filtration media available. This superb filter textile has an extremely high dust rejecting surface and dust will not easily clog . With Gutter Master® 2040 filter system you will not need to spend any further monies on continually purchasing new filters.

Another first from ACS™ is our stainless steel 210 litre Gutter Master® conical waste hopper with bottom discharge opening gate, this allows you to empty waste after every job into a typical plastic basket (supplied) lined with heavy duty plastic bags.

Now you can empty into bags, tie them off and deal with them at the end of the day if you are not able to dispose of the collected waste at your clients premises. This collection receptacle is optional. Standard supply is the 205 Litre dangerous goods collection drum fitted with a liquid drain valve.

03th Oct 2018

The proven complete gutter vacuum cleaning system from ACSTM

|

|

|

|

|

|

|

|

|

Custom Designed Systems

Special council request to cage the engine platform for safety and security and include external controls |

|

27th Sep 2018

|

|

|

|

|

Engine powered vacuum system 10Hp Vanguard with 3 years engine warranty

Easy role on and role off Specially designed for mobility, allows cleaning of gutters from the safety of the ground

Australian designed and manufactured Supporting local businesses |

|

- 10 hp Vanguard engine, 3 years warranty

Regenerative heavy duty industrial, no maintenance vacuum producer

Cyclonic waste drum interceptor head

10 metres Gutter Master® clear 63mm smooth bore vacuum hose

Gutter Master® Carbon fiber clean from the ground pole kit 6 metre reach (Optional)

Custom steel powder coated waste container

Galvanised steel engine roll frame platform

Cyclonic waste drum head with 100 litre container on wheels

Pneumatic wheels fitted for easy maneuvering

Vacuum system protection valve and filtration system

Teflon coated washable vacuum filter

Wet and dry capabilities

620mm wide ,fits through standard house door ways

Lightweight and portable design

Gutter Master® 1030

Introducing Our Latest Generation Gutter Master® 1030

The Gutter Master® 1030 system has been introduced to fill the void in the market for a modular/mobile engine powered industrial grade vacuum system. The complete system weighs just over 90Kg! complete with a cyclonic action waste drum, fitted with industrial pneumatic wheels and coupling together design allows easy maneuverability at any property

Gutter Master® 1030 is an Australian designed and manufactured, complete gutter vacuum cleaning system. As the professional’s choice it was specifically developed for fast and profitable gutter vacuum cleaning from the safety of the ground.

We have designed the 1030 so it can be easily transported in a 6x4 trailer or a small commercial van then rolled off at the work site, couple the system together and move it around to gain access through standard doorways to gain access to the rear or side of properties. If you are a garden service provider, you will more than likely have a trailer that can easily accommodate the 1030 system.

Hand scoop cleaning gutter channels and roof valleys can be a tiring and time consuming process. Hanging onto a ladder or crouching down at a roof line edge can become hard on your knees, ankles and feet. Wet, messy, gutter slop often has to be hand scraped into buckets that gets heavier as you move along. By flicking the muck down to the ground and using regular blower vacs, you just end up having to double handle the silt you threw or leaves you blew off the roof. The Gutter Master® 1030 allows you to vacuum clean roof gutter channels from the safety of the ground utilising our Gutter Master® carbon fiber vacuum pole kit that can be supplied to heights of up to 14 metres.

Gutter Master® 1030

Industrial Vacuum Performance Gives You The Power You Require

Gutter Master® 1030 generates vacuum by incorporating a regenerative side channel vacuum producer, this style of vacuum producer generates 50% more vacuum pressure when compared against regular drum type industrial electric vacuum cleaners.Collect the waste using vacuum, no more mess and or double handling, Gutter Master® vacuum technology will clean gutters 3 times faster than hand scooping methods.

A Vanguard 10 hp 4 stroke engine is used to drive the vacuum producer via a twin belt industrial drive system, a service portal is easily accessible to enable simple belt tensioning requirements. The engine is supplied with a worldwide 3 year warranty backed by Briggs & Stratton. Of course all this power needs protection to ensure the system continues to operate trouble free, an over pressure relief valve is fitted to protect the vacuum from overheating. A wet and dry filter is fitted with pre filter to prevent dust contamination into the vacuum producer. Most of the components are either manufactured from galvanized,stainless steel or have received an industrial powder coated finish to protect them from the day to day elements.

Gutter Master® 1030

Top Of The Line Components And High Efficient Filter

Gutter Master® 1030 features a long life high efficiency dust wet and dry filter system. The dusty air is filtered by a large primary air filter that is suspended in a filter housing. Featuring a proven textile filter spun bonded polyester, this material can be washed clean 100’s of times and re used. It is one of the world's highest quality air filtration media available.

Gutter Master® 1030 waste drum is designed so it can be removed and emptied simply and efficiently then placed back onto the systems coupling attachment. The cyclonic drum top interceptor provides excellent separation of heavy to medium weight material.

Gutter Master® 1030

Rear Access And Sloping Roof Solutions Another Gutter Master® First

Some properties represent challenges and cannot be vacuum cleaned from the roof due to the pitch of the roof, heights and access points. Our Gutter Master® carbon fiber modular vacuum poles enable you to clean any property from the safety of the ground, poles can reach heights of up to 4 storeys.Experience has displayed to us that access to the rear and side of certain properties cannot be easily achieved with vehicle/trailer mounted systems, this problem was solved by ACS™ with the introduction of the Gutter Master® 1030 modular system. Designed to be easily moved around and able to fit through a standard residential door way and end all access issues you may encounter at any property.

Thinking of getting involved in the lucrative Gutter vacuum cleaning market, call us and discuss your needs and requirements, we can arrange easy finance options , teach you how to use the equipment and deliver safe efficient services that will allow you to make money from day 1 of purchase.

Not sure how to set up the system on your vehicle or trailer just ask, we have installed over 200 systems onto clients vehicles/trailers we will have a design layout to fit.Do you want a custom set up with large waste tanks, twin operator systems and or fitted onto a specific set up, contact us to discuss your specific requirements. As all fabrication and design are done in house and right here in Australia you can be assured that the finished system will be correct the first time.

10th October 2018

Struggling to get more jobs?

|

|

We see that the residential gutter cleaning service sector is in continual high demand. Why? We have an ongoing aging population who will no longer use a ladder to clean their own gutters, then we have the younger generation who are just too busy and outsource most residential maintenance requirements.

As Australia's leading manufacturer of Gutter vacuum cleaning systems, we receive more inquiries from companies looking at starting a lucrative gutter cleaning business using our professional industrial high-powered vacuum systems. We are not a franchise operation and have been supplying professional machines and advice to local companies since 1999. |

|

Super Mini

These are compact industrial portable vacuums that allow raising the hopper and dumping collected material into a tote box, NOT on the floor as competitive machines do. These compact industrial portable vacuums offer two types of vacuum producer, positive displacement or regenerative vacuum pump. Both are designed and rated for continuous duty.

Mini

The Mini Series compact vacuums cleaners are portable, completely assembled, and will fit through a 2.5 m high door. The Mini Series can also be optioned as explosion proof vacuums and have been designed for continuous duty. The standard 700 Litre hopper capacity means less time traveling to dump material and more time working.